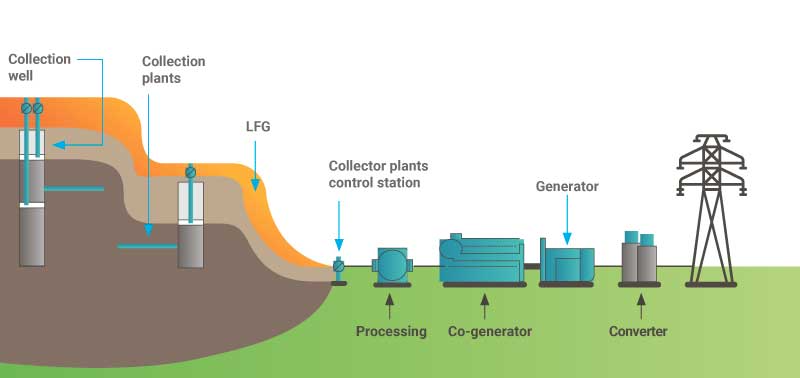

New possibilities to reduce biogas dispersion into the atmosphere and eliminate odorous landfill emissions

Automation, monitoring, and continuous control of the landfill biogas capture system is the best practice for increasing plant extraction efficiency.

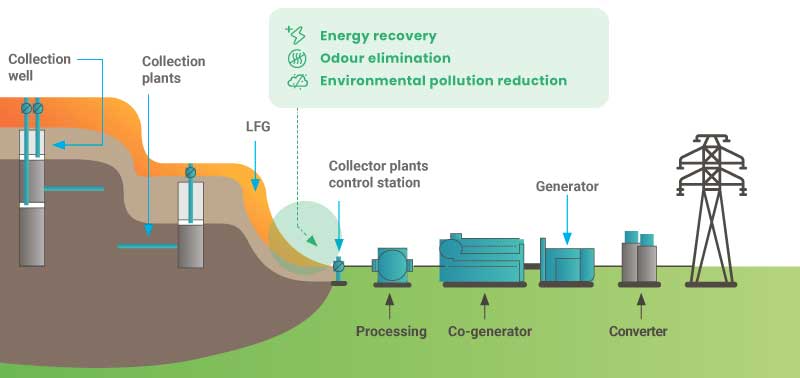

Reduction of environmental pollution

The new automation systems applied to the collector plants in the landfill are decisive in reducing the dispersion of methane generated by waste into the atmosphere, a gas considered to be one of the factors responsible for the current climate-changing effects (read EU-US Global Methane Commitment of 18.09.21). With continuous and real time remote control, the automation systems increase the amount of recovered biogas to be used for energy production.

The comparative LCA assessment – carried out by NIER INGEGNERIA according to ISO 14040:2021 and ISO 14044:2021 standards – showed that the use of automation and remote control products brings positive impacts in terms of environmental benefits in relation to the many environmental aspects analysed, including Global Warming (GW100a), Terrestrial Ecotoxicity, Primary Energy, etc.

The most encouraging data to emerge from the comparison between a manual and an automated collection system is the drastic reduction of CO2 eq dispersed into the atmosphere (carbon footprint reduction).

Improvement of odour emissions

In addition to increasing biogas extraction volumes, automation systems reduce odour emissions from landfilled waste to the point of complete elimination. This results in greater sustainability towards communities and the environment, in line with the current demands of the European Green Deal.

The comparative LCA study also showed positive impacts, i.e. benefits, regarding Human Toxicity and Terrestrial Ecotoxicity.

Increasing energy efficiency

The first area in which automation and continuous real-time monitoring have a decisive impact is in increasing the lower calorific value (PCI) of biogas sent for recovery and in increasing energy efficiency for plants.

The studies carried out on the first products available on the market show how automation systems (those that perform the analysis of the main biogas parameters for each collection line, each connected to a landfill well) are able, through continuous monitoring and self-adjustment, to intervene in a targeted and punctual manner to improve the quality of the captured biogas.

Application examples

The first products responding to these new best practices are available on the market in terms of greater energy efficiencies and odour reductions through automation and remote control.

The most important data and figures see among the first applications in the field the Gas Stabiliser product, patented as a system and method.

For further information or direct contact with engineers Francesca Sandrini and Marco Antonini